According to foreign media reports, the UK has led a research and development cooperation to develop and produce high strength aluminium alloys using fully recycled metals. Aluminum production consumes 3.5% of the world's electricity supply, and its carbon dioxide emissions account for 1% of the total global carbon dioxide emissions.

According to foreign media reports, the UK has led a research and development cooperation to develop and produce high strength aluminium alloys using fully recycled metals. Aluminum production consumes 3.5% of the world's electricity supply, and its carbon dioxide emissions account for 1% of the total global carbon dioxide emissions.

However, in theory, metal can be recycled by wireless, and the energy consumption of recycling only accounts for nearly 5% of the energy consumption of the initial production of metal. Since 1908, global aluminium production has exceeded 1 billion tons, of which more than 75% are in stock.

Research and Development of High Strength Aluminum Alloy Powered Vehicle Lightweight by BCAST and Kenlian Aluminum Industry

In order to realize the full utilization of aluminium materials and recycling, BCAST of Brunel University and Constellium of Netherlands signed a strategic R&D cooperation agreement.

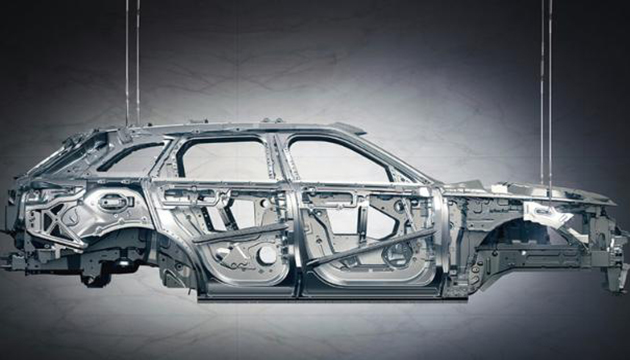

Both sides aim to develop high performance aluminium alloys and apply their products to lightweight automotive structures. Aluminum alloys have many advantages, including low density, high strength and high corrosion resistance. Therefore, the demand for aluminium products continues to grow, especially in the transportation industry.

However, aluminium automobile parts can also significantly reduce vehicle emissions, while ensuring that vehicles can travel 10,000 miles.

STEP will develop a new generation of alloys, which will give super-high strength to aluminium alloys, double the strength of traditional alloys, and ensure excellent ductility, crashworthiness and thermal conductivity.

Researchers will use a variety of product technologies, including deforming and reducing the particle size of alloys, to enhance the overall strength of metals.

Researchers also plan to develop a new melt conditioned direct chill (MC-DC) casting process to densely cut liquid metals before solidification.

MC-DC casting process can provide high quality aluminium fillers. Because of its finer crystalline particles, which can enhance the strength of materials, the processing process will be simplified in the future.

粵公網(wǎng)安備 44098102441101號(hào)

粵公網(wǎng)安備 44098102441101號(hào)